Industry Trends of Dimethomorph Fungicide and Combination Products

The global dimethomorph fungicide market has consistently expanded, reaching an estimated USD 420 million in 2023. Combination formulations such as ametoctradin dimethomorph and dimethomorph + pyraclostrobin represent an emerging segment, driven by demands in high-value horticultural, fruit, and vegetable crops. Adoption of innovative active ingredient blends is encouraged by resistance management needs, enhanced efficacy, and lower overall input costs, particularly in the European and Asian markets. Regulatory frameworks push for higher technical standards (e.g., ISO, FAO specs), further promoting advanced synthesis and formulation technology within the supply chain.

Technical Specifications Overview

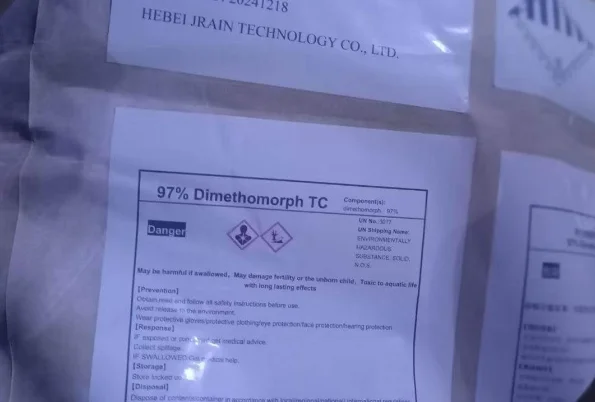

Dimethomorph 98%TC (Technical Concentrate) offers the highest available active content for agro-ingredient mixtures. Key parameters for widely utilized products are compiled below.

Product | Active Ingredient | Purity (%) | Formulation | Key Application |

Dimethomorph 98%TC | Dimethomorph | 98.0 Min | TC/WG/SC | Vegetables, Potatoes |

Ametoctradin Dimethomorph | Ametoctradin+Dimethomorph | 27.5+20 | SC/OD | Fruits, Grapes |

Dimethomorph + Pyraclostrobin | Dimethomorph+Pyraclostrobin | 30+6 | SC/WG | Vegetables, Leaf Crops |

Manufacturing Process and Quality Standards

The production of dimethomorph fungicide and its combinations involves multistage chemical synthesis, precision blending, and controlled granulation. Key steps include high purity raw material selection, catalytic reactions at defined temperature/pressure, followed by crystallization—frequently monitored through HPLC and GC-MS analysis. For formulated products, spray drying or extrusion is used (e.g., for WG—water dispersible granules). Stringent in-house QA protocols, with ISO 9001:2015 and ISO 17025 testing certification, guarantee compliance with global regulatory and export standards.

Diagram: Dimethomorph Combination Manufacturing Steps

1. Raw Material Procurement → Chemical Synthesis (Alkylation, Condensation)

2. Intermediate Purification → Crystallization

3. Formulation Blending (SC, WG, OD)

4. Granulation / Micro-encapsulation

5. Lab Testing (HPLC, GC), Stability Analysis

6. Packaging (ASEPTIC, Tamper-proof), Traceable Labelling

Service life, product performance, and shelf-life are validated under international shelf-life simulation standards, ensuring durability and reliable plant protection.

Application Scenarios and Technical Advantages

Dimethomorph fungicide is widely employed for late blight and downy mildew management in tomatoes, grapes, cucurbits, and other high-value crops. Its strong systemic activity, unique mode-of-action (MOR Group 40), and translaminar movement deliver lasting defense, even in variable environments. When used in blends, such as ametoctradin dimethomorph, dual-site action and resistance prevention are achieved, reducing chemical input by up to 35% compared to solo applications.

The dimethomorph + pyraclostrobin mixture provides both protective and curative effects, especially valued in ornamental and greenhouse vegetable production, where phytotoxicity and residue profiles are tightly regulated.

· Extended control window (up to 14 days after treatment).

· High rainfastness and frost-resistance (validated by OECD trials).

· No negative impact on beneficial soil microflora.

· Registered for use in the EU, China, India, and Brazil.

Competitive Manufacturer Comparison

Company | Main Product | ISO Cert. | Batch Consistency | Custom Formulation | Lead Time (Days) |

Company A | Dimethomorph 98%TC | ISO 9001 | ≥99% | Yes | 17 |

Company B | Ametoctradin Dimethomorph SC | ISO 9001/14001 | ≥98% | Yes | 21 |

Company C | Dimethomorph + Pyraclostrobin WG | ISO 9001/45001 | ≥99% | Yes | 14 |

All listed companies maintain full traceability and provide batch analysis reports on request, supporting transparency and international procurement requirements.

Custom B2B Solutions & Application Case Examples

B2B procurement of dimethomorph fungicide emphasizes tailored mixes, private labeling, and on-site technical training. For example, a leading vegetable processor in the EU switched to ametoctradin dimethomorph SC custom-packed in water-soluble bags, resulting in a 22% reduction in waste packaging and a 16% improvement in disease control consistency over two consecutive growing seasons.

Another client in Southeast Asia selected a bespoke dimethomorph + pyraclostrobin WG blend with anti-caking additives for high-humidity environments, eliminating seasonal product caking—a previous cause of 9% application loss per batch.

Data Visualization: Parameter and Performance Charts

Performance Comparison (Efficacy %)

Dimethomorph 98%TC92%

Ametoctradin Dimethomorph98%

D. + Pyraclostrobin95%

Market Share 2023

Dimethomorph

36%

Dimethomorph 36%

Am.+Dimethomorph 20%

D.+Pyraclostrobin 44%

Parameter | Dimethomorph 98%TC | Ametoctradin Dimethomorph | Dimethomorph + Pyraclostrobin |

pH (1% soln) | 7.5–8.5 | 6.8–8.1 | 7.1–8.2 |

Water Dispersibility (%) | ≥96 | ≥95 | ≥97 |

Suspensibility (%) | ≥90 | ≥92 | ≥93 |

Particle Size (μm) | <120 | <100 | <95 |

FAQ: Technical Terms and Practical Details

1. What is the mode-of-action of dimethomorph?

Dimethomorph disrupts cell wall synthesis in oomycete pathogens, acting as a systemic, protectant and curative active (FRAC Group 40).

2. What are the most common formulations?

Primary forms include Technical Concentrate (TC), Suspension Concentrate (SC), Water-Dispersible Granules (WG), and Oil Dispersion (OD).

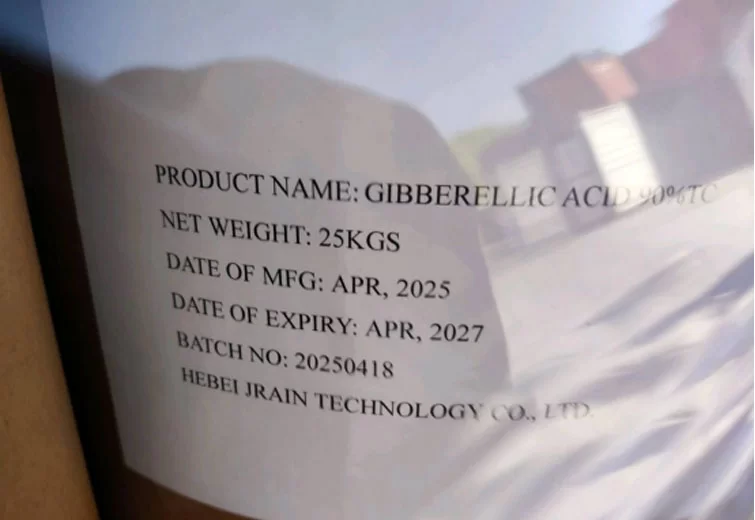

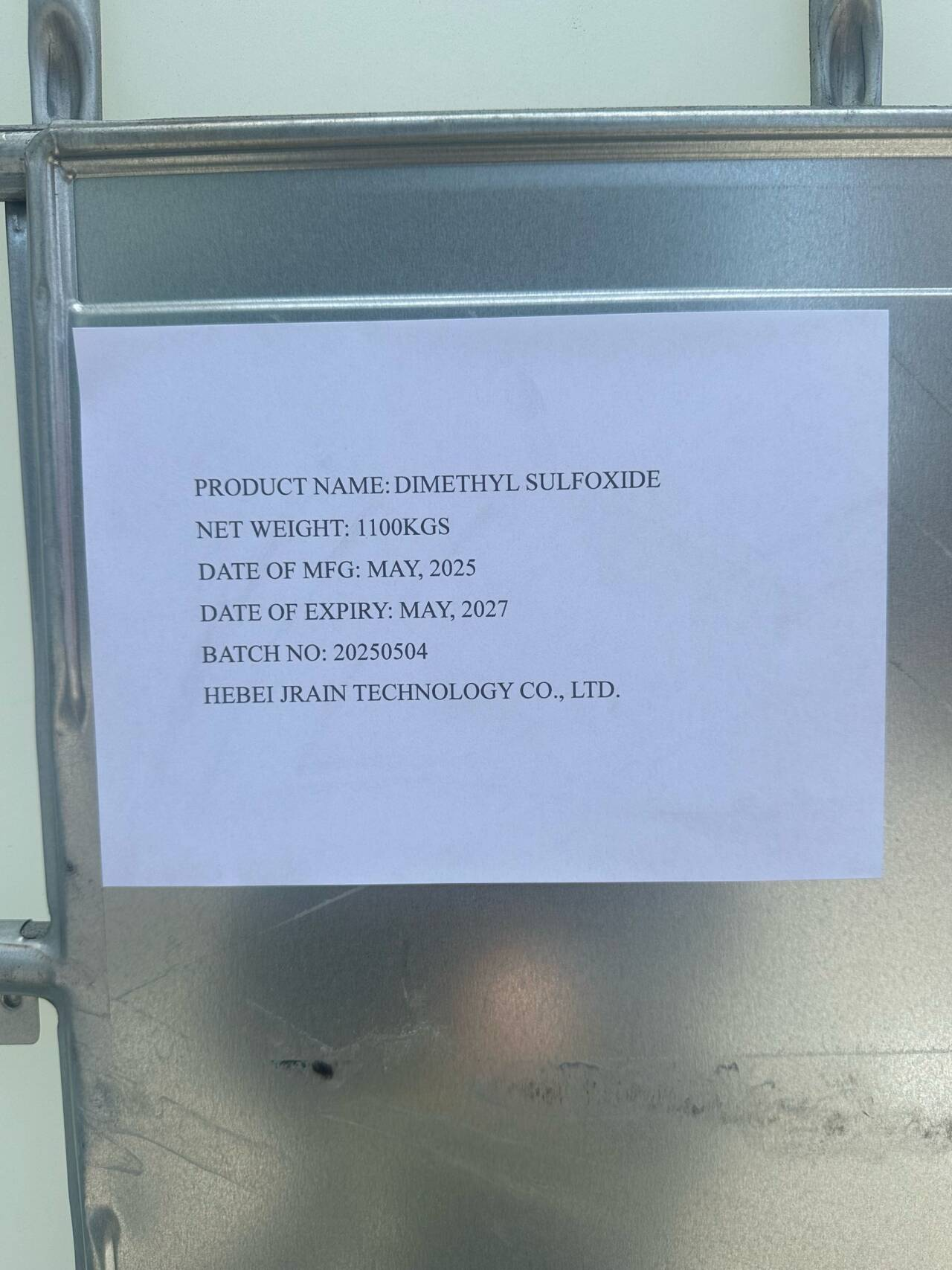

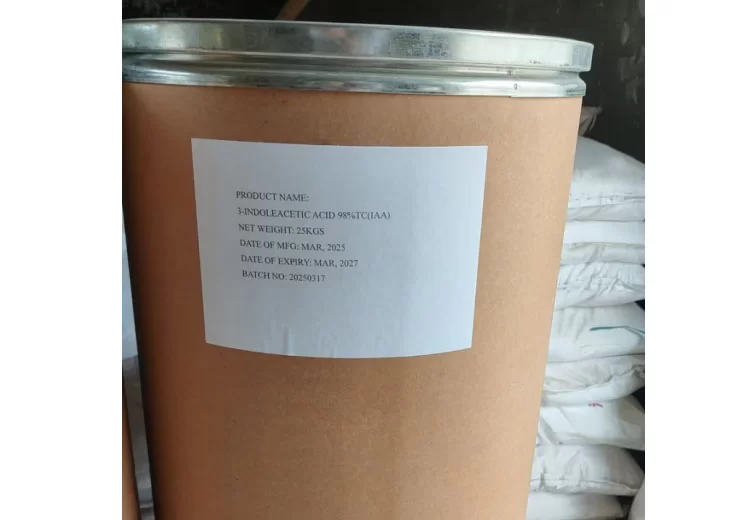

3. Which packaging standards are used?

Packaging is validated to UN/FAO agrochemical transport standards, with tamper-evident HDPE, FFS, or aluminum-laminate bags available up to 25kg.

4. Can blends be customized for local disease spectrum?

Yes. B2B partners can specify actives ratio, formulation matrix, adjuvants, and pack sizes for optimal field results.

5. What typical shelf-life and storage conditions apply?

36–48 months at 0–40°C; validated by accelerated aging (ISTA/ISO 18664) and field sampling for content retention.

6. Which installation or application standards are followed?

Application is in line with local GAP and OECD residue guidelines, with equipment calibration following ISO 16119/EN 13790.

7. How are quality and origin verified?

Each batch is supported by Certificate of Analysis (COA), ISO manufacturing certificate, and third-party lab validation reports (SGS/BV).

Delivery, Warranty and Customer Support

· Standard lead time for custom dimethomorph fungicide or combinations: 12–21 days after PO and label approval.

· Shelf-life assurance: min. 36 months, backed by batch retention and after-sales monitoring.

· Multi-lingual technical hotline, field troubleshooting, and free trial samples for B2B partners.

· Dedicated account managers with >8 years industry experience.

References

1. Journal of Agricultural and Food Chemistry

2. Pesticide Science & Crop Protection

3. FRAC Code List (CropLife International)

4. ISO 9001/17025 Certification Bodies

5. OECD Guidelines for Residue Trials

6. International Society for Plant Pathology