The Imperative Role of Advanced Chemical Mixing Systems in Modern Industry

In the dynamic landscape of industrial manufacturing, the precision and efficiency of chemical mixing systems are paramount. From pharmaceuticals to petrochemicals, food & beverage to water treatment, the homogeneity and integrity of final products hinge critically on robust liquid blending system technologies. These systems are not merely agitators; they represent sophisticated engineering solutions designed to optimize reaction kinetics, ensure consistent product quality, and enhance process safety. As industries demand higher purity, tighter tolerances, and increased sustainability, the evolution of mixing technology continues to push the boundaries of performance and reliability.

This comprehensive guide delves into the intricate world of advanced blending solutions, offering insights crucial for B2B decision-makers and technical personnel. We explore the latest industry trends, detailed technical parameters, diverse application scenarios, and the tangible advantages offered by state-of-the-art chemical mixing systems. Our objective is to provide a fact-based, technical perspective that illuminates the value proposition of investing in superior mixing technologies, including a focus on the manufacturing prowess, quality assurance, and customized engineering that defines leading providers in this sector.

Industry Trends and Technological Evolution in Liquid Blending Systems

The industrial mixing sector is undergoing significant transformation, driven by demands for greater automation, energy efficiency, and predictive maintenance. Current trends highlight a shift towards intelligent liquid blending system solutions integrating IoT sensors and AI-driven analytics for real-time process optimization. This allows for dynamic adjustments to mixing parameters based on live feedback, significantly reducing material waste and energy consumption. For instance, advanced computational fluid dynamics (CFD) modeling is now routinely employed during the design phase to predict flow patterns and optimize impeller geometries, ensuring maximum mixing efficiency with minimal power input.

Sustainability is another major driver, leading to the development of chemical mixing systems with smaller footprints, reduced cleaning times, and improved material recovery rates. New material alloys and surface coatings are being utilized to enhance corrosion resistance and extend equipment lifespan, particularly in highly aggressive chemical environments. Furthermore, modular designs are gaining traction, offering greater flexibility for process scaling and easier integration into existing production lines. These advancements underscore a collective industry effort to achieve higher operational excellence and address evolving regulatory compliance standards, particularly within critical sectors like pharmaceuticals and fine chemicals where batch consistency is non-negotiable.

Core Technologies and Technical Parameters of Chemical Mixing Systems

At the heart of effective chemical mixing systems lies a diverse array of technologies, each optimized for specific fluid properties and process objectives. Agitator-based systems, for example, employ various impeller designs—propeller, turbine, hydrofoil—to generate desired flow patterns (axial, radial, tangential) and shear forces. Static mixers, conversely, achieve homogenization through engineered elements within a pipe, relying on fluid velocity to create turbulence and promote intermixing without moving parts. High-shear mixers are critical for emulsification, dispersion, and particle size reduction, operating at high rotational speeds to impart intense mechanical energy.

Key technical parameters that define the performance of a liquid blending system include:

· Viscosity Range: The ability to handle fluids from extremely low (e.g., water) to very high (e.g., polymers, slurries), often quantified in centipoise (cP).

· Shear Rate: The gradient of velocity within the fluid, crucial for dispersing solids or forming emulsions. Measured in s-1.

· Power Consumption: The energy required to operate the mixer, directly impacting operational costs. Typically measured in kilowatts (kW).

· Mixing Time: The duration required to achieve a specified level of homogeneity, a critical factor for batch processes.

· Material Compatibility: The chemical resistance of wetted parts to the process fluid, essential for preventing corrosion and contamination.

· Temperature and Pressure Ratings: The operational limits under which the system can safely and effectively function.

Understanding these parameters is vital for selecting and sizing the optimal mixing solution, ensuring that the system delivers consistent and predictable results while maintaining operational efficiency and safety across various industrial applications.

General Chemical Mixing System Parameters

Parameter | Typical Range/Value | Unit/Description |

Volume Capacity | 50 L – 50,000 L+ | Liters or Gallons |

Motor Power | 0.75 kW – 150 kW+ | Kilowatts (kW) |

Max. Viscosity | 1 cP – 1,000,000 cP | Centipoise (cP) |

Operating Temperature | -20°C to 200°C | Degrees Celsius |

Pressure Rating | Atmospheric to 25 Bar | Bar or PSI |

Materials of Construction | 304/316L SS, Hastelloy, Titanium, PTFE-lined | Specific Alloy/Coating |

Manufacturing Excellence and Quality Assurance for Liquid Mixing Systems

The robust performance and longevity of any liquid blending system are directly attributable to its manufacturing process and the stringent quality controls applied. A leading manufacturer adheres to a meticulously defined process flow, ensuring every component meets exacting standards. This typically begins with the selection of premium-grade materials, such as 316L stainless steel for its superior corrosion resistance in aggressive chemical environments, or specialized alloys like Hastelloy for extreme conditions.

The manufacturing journey for a high-quality chemical mixing system involves several critical stages:

1. Material Selection & Preparation: Sourcing certified raw materials (e.g., ASTM standards for stainless steel).

2. Precision Fabrication: Advanced techniques like CNC machining for precise component dimensions, laser cutting for intricate parts, and skilled welding (TIG, MIG) for structural integrity.

3. Surface Treatment & Finishing: Polishing (e.g., down to Ra < 0.8 µm for pharmaceutical applications), passivation, and specialized coatings to enhance hygiene, prevent adhesion, and improve corrosion resistance.

4. Assembly & Integration: Careful assembly of motors, gearboxes, impellers, shafts, and sealing systems, often in cleanroom environments for sensitive applications.

5. Rigorous Testing & Inspection: Comprehensive checks including hydrostatic pressure tests, functional performance tests, vibration analysis, and material traceability verification. Adherence to standards such as ISO 9001 for quality management, ANSI/ASME for pressure vessels, and industry-specific certifications like FDA for food/pharma contact surfaces.

Such meticulous attention to detail during manufacturing directly translates into tangible advantages: extended service life (often exceeding 15-20 years with proper maintenance), minimal downtime, and consistent performance. For example, in petrochemical applications, the resistance to highly corrosive media achieved through precise material selection and fabrication ensures operational safety and significantly reduces maintenance costs. In wastewater treatment, the robust construction ensures reliable operation despite abrasive slurries and continuous duty cycles, contributing to consistent effluent quality.

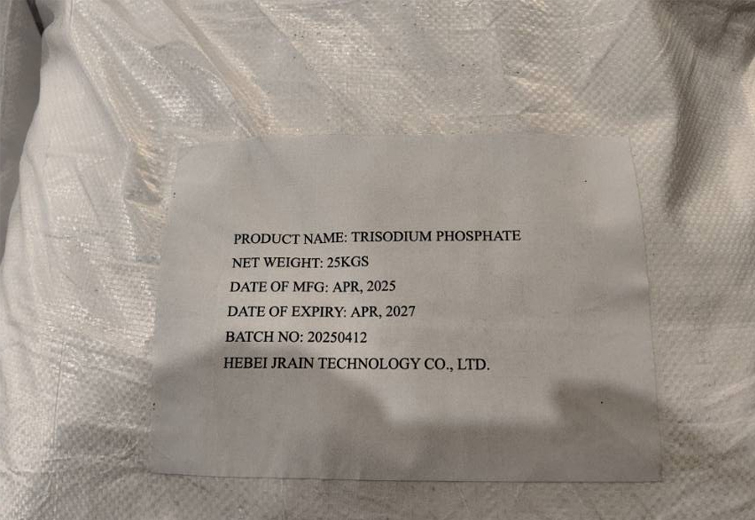

Figure 1: Illustration of typical components within advanced chemical mixing systems, showcasing robust construction.

Diverse Application Scenarios and Proven Case Studies

The versatility of advanced chemical mixing systems makes them indispensable across a multitude of industries. Their capability to handle a wide range of viscosities, temperatures, and reactivities ensures optimal process outcomes in diverse environments.

· Petrochemical Industry: Used for blending various crude oil derivatives, catalyst suspension, and polymer processing. High-torque liquid blending system agitators ensure uniform temperature distribution in large reactors, preventing hot spots and enhancing reaction yields while optimizing energy consumption.

· Pharmaceutical & Biotech: Critical for preparing sterile media, dissolving active pharmaceutical ingredients (APIs), and cell culture mixing. Systems must meet strict cGMP guidelines, featuring sanitary designs, CIP/SIP capabilities, and high-purity materials to prevent contamination and ensure product efficacy.

· Food & Beverage: Employed in blending syrups, sauces, dairy products, and fermentation processes. The focus is on hygienic design, gentle mixing to preserve product integrity, and efficient heat transfer. For example, in yogurt production, a precise liquid blending system ensures consistent texture and flavor by uniformly incorporating fruit purees and cultures.

· Water & Wastewater Treatment: Essential for flocculation, neutralization, and chemical dosing. Large-scale chemical mixing systems ensure efficient dispersal of coagulants and disinfectants, crucial for maintaining water quality and meeting environmental discharge standards. The anti-corrosion properties of chosen materials are vital here.

· Mining & Metallurgy: Utilized for slurry preparation, leaching processes, and reagent conditioning. Robust mixers are designed to handle abrasive and high-density slurries, ensuring effective mineral recovery and process efficiency.

Case Study Snippet: Large-Scale Polymerization Reactor A major chemical manufacturer faced challenges with inconsistent polymerization rates and localized overheating in a 20,000-liter reactor. Implementing a custom-designed liquid blending system featuring a high-efficiency hydrofoil impeller and enhanced baffling led to a 15% reduction in batch cycle time and a 20% improvement in product uniformity, directly contributing to substantial cost savings and increased throughput. This success was attributed to the system's ability to create an optimal flow regime, effectively dissipating heat and ensuring uniform monomer distribution.

Technical Advantages and Return on Investment (ROI)

Investing in advanced chemical mixing systems yields significant technical advantages that translate directly into a compelling return on investment. The primary benefit is enhanced process efficiency. Optimized impeller designs and motor-gearbox configurations can reduce power consumption by up to 30% compared to older, less efficient systems, leading to substantial energy cost savings over the equipment's lifespan. Furthermore, improved mixing homogeneity reduces batch variability, minimizes off-spec products, and decreases the need for rework, thus saving raw material costs and operational time.

Beyond direct cost savings, modern liquid blending system solutions contribute to superior product quality and safety. Precise control over mixing parameters ensures consistent particle dispersion, uniform heat transfer, and complete dissolution, all of which are critical for end-product performance and customer satisfaction. The integration of advanced sealing technologies, such as double mechanical seals with barrier fluid systems, prevents leakage of hazardous chemicals, safeguarding personnel and the environment. Reduced maintenance requirements, thanks to robust construction and predictive analytics, further contribute to a lower total cost of ownership (TCO) and improved uptime, providing a tangible ROI that extends far beyond the initial capital expenditure.

Manufacturer Comparison and Customization Solutions

Choosing the right provider for chemical mixing systems involves evaluating more than just price; it requires a deep dive into engineering capabilities, manufacturing quality, and aftermarket support. Leading manufacturers differentiate themselves through their commitment to research and development, offering innovative solutions tailored to specific process challenges. Key factors for comparison include their expertise in CFD modeling, availability of pilot-scale testing facilities, and a track record of successful installations in demanding environments.

Customization is often the cornerstone of optimal liquid blending system performance. A generic off-the-shelf mixer may fall short when dealing with highly viscous fluids, shear-sensitive materials, or complex multi-phase reactions. Bespoke solutions involve:

· Impeller Design Optimization: Tailoring impeller type, diameter, and number to the fluid rheology and desired mixing intensity.

· Tank & Baffle Configuration: Designing tank geometry and baffle placement to eliminate dead zones and optimize flow patterns.

· Material Specification: Selecting corrosion-resistant alloys, specialized coatings, or sanitary finishes based on process fluid and industry standards.

· Sealing Solutions: Customizing mechanical seals, packing glands, or magnetic drives to prevent leaks and ensure compliance with environmental and safety regulations.

· Instrumentation & Control: Integrating sensors for temperature, pH, viscosity, and robust control systems for automated operation and data logging.

A thorough vendor comparison should also consider service longevity, spare parts availability, and the provision of technical training for operational and maintenance staff. A reputable manufacturer offers comprehensive support from initial consultation and design through installation, commissioning, and ongoing service, ensuring the maximum operational lifespan of the chemical mixing system.

Comparative Overview: Liquid Blending System Features

Feature | Standard Model | Advanced Series | Custom Engineered |

Impeller Type | Propeller, Pitched Blade | Hydrofoil, Radial Turbine | Application-Specific (e.g., High-Shear, Anchor) |

Control System | Manual, Basic VFD | Integrated PLC, HMI | Advanced DCS Integration, SCADA, IoT Readiness |

Sealing Mechanism | Lip Seal, Single Mech. Seal | Double Mech. Seal w/Barrier System | Magnetic Drive, Dry Gas Seal (Application Dependant) |

Material Options | 304/316 SS | 316L SS, Duplex SS | Hastelloy, Titanium, PTFE-lined, Exotic Alloys |

Certifications | ISO 9001 | ISO 9001, CE, ATEX, basic ASME | Full ASME, PED, FDA, EHEDG, cGMP Compliance |

Data Visualization: Performance Metrics for Liquid Mixing Systems

The efficacy of a liquid blending system can be clearly demonstrated through key performance indicators. Below, we present simulated data illustrating the performance across different mixer types and operational efficiencies.

Liquid Mixing System Technical Indicators (Simulated)

Metric | Standard Agitator | High-Efficiency Hydrofoil | High-Shear Mixer |

Power Consumption (kW/m³) | 0.85 | 0.60 | 1.20 |

Mixing Time (min for 95% homogeneity) | 25 | 18 | 10 |

Typical Application Viscosity (cP) | 100 – 10,000 | 1 – 5,000 | 1 – 1,000 |

Typical Shear Rate (s⁻¹) | 50 – 200 | 20 – 150 | 500 – 5,000+ |

Frequently Asked Questions (FAQ) about Chemical Mixing Systems

1. What is the typical service life of a well-maintained Liquid Mixing System?

With proper selection of materials, robust manufacturing, and adherence to maintenance schedules, a high-quality liquid blending system can reliably operate for 15 to 25 years or even longer. Factors like corrosive environment, operating temperature, and continuous duty cycles can influence this, but engineered solutions are designed for longevity.

2. What are the key inspection standards for chemical mixing systems?

Key standards include ISO 9001 for quality management systems, ASME BPV Code (Section VIII) for pressure vessels, ANSI standards for piping and flanges, and sometimes industry-specific guidelines like FDA (21 CFR Part 11) for pharmaceutical applications or EHEDG for hygienic design in food processing. Reputable manufacturers adhere to these to ensure safety and performance.

3. How does material selection impact the efficiency and cost of a chemical mixing system?

Material selection is crucial. Using inappropriate materials can lead to rapid corrosion, product contamination, and frequent component replacement, significantly increasing operational costs and downtime. For instance, 316L stainless steel offers excellent corrosion resistance for many chemicals, while exotic alloys like Hastelloy are used for highly aggressive media to ensure maximum service life and prevent costly failures.

4. Can a liquid blending system be customized for shear-sensitive products?

Absolutely. For shear-sensitive products, specialized impellers (e.g., hydrofoils, helical ribbon), lower rotational speeds, and optimized tank geometry are employed to ensure gentle mixing while still achieving homogeneity. CFD simulations are often used to predict and minimize shear forces within the vessel for such delicate applications.

5. What is the typical delivery timeframe for a customized chemical mixing system?

Delivery times vary greatly depending on complexity, size, and material availability. Standard units might be 8-12 weeks, while highly customized chemical mixing systems requiring specialized fabrication and lengthy material lead times could range from 16 to 30 weeks. Expedited options may be available depending on project urgency.

6. What warranty is typically offered on industrial liquid blending systems?

Most reputable manufacturers offer a standard warranty, typically 12 to 24 months from the date of commissioning or 18 to 30 months from shipment, whichever comes first. This warranty covers defects in materials and workmanship under normal operating conditions. Extended warranty options and comprehensive service contracts are also often available.

7. How important is after-sales support for long-term operational success?

After-sales support is critical. It includes technical assistance, spare parts availability, preventive maintenance services, and operator training. Robust support ensures minimal downtime, optimized performance throughout the equipment's lifespan, and quick resolution of any operational issues, maximizing the ROI of your liquid blending system.

Commitment to Excellence and Customer Trust

Our dedication to providing top-tier chemical mixing systems is rooted in an unwavering commitment to engineering excellence, quality manufacturing, and comprehensive customer support. We understand that for B2B clients, the reliability and performance of a liquid blending system are directly tied to their operational efficiency and product integrity. We pride ourselves on transparent communication regarding project timelines, from initial design consultation to final commissioning.

Our robust quality assurance protocols, including adherence to international standards like ISO 9001 and specific industry certifications (e.g., ASME, PED, FDA, EHEDG), ensure that every system delivered meets the highest benchmarks for safety, performance, and durability. We offer detailed delivery schedules, comprehensive documentation packages, and an industry-leading warranty to instill confidence. Our global network of service engineers provides responsive technical assistance, spare parts, and preventive maintenance, guaranteeing the sustained peak performance of your investment.

Authoritative References

1. Paul, E. L., Atiemo-Obeng, V. A., & Kresta, S. M. (2004). Handbook of Industrial Mixing: Science and Practice. John Wiley & Sons.

2. Oldshue, J. Y. (1983). Fluid Mixing Technology. McGraw-Hill.

3. Wang, J., & Xu, J. (2018). Computational Fluid Dynamics for Chemical Engineering. Springer.

4. Myers, K. J., & Kresta, S. M. (2017). "Mixing in the Chemical and Process Industries." Chemical Engineering Progress, 113(10), 30-36.

5. European Hygienic Engineering & Design Group (EHEDG) Guidelines. (Ongoing Publications).

6. American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. (Latest Edition).