The Crucial Role of Plant Growth Regulators: Indole-3-Butyric Acid & Naphthalene Acetic Acid

In the rapidly evolving landscape of modern agriculture and horticulture, the strategic application of plant growth regulators (PGRs) is paramount for optimizing crop yields, enhancing plant development, and ensuring sustainable cultivation practices. Among the most potent and widely utilized PGRs are Indole-3-Butyric Acid (IBA) and Naphthalene Acetic Acid (NAA). These compounds are auxins, a class of plant hormones vital for cell elongation, division, and differentiation. Manufacturers offering high-purity indole-3-butyric acid for sale and advanced formulations of 1 naphthaleneacetic acid are driving innovation, helping growers achieve superior outcomes in propagation, rooting, and fruit management. Understanding the nuanced applications and technical specifications of these substances is key for agricultural professionals seeking to maximize their operational efficiency and product quality.

The global market for PGRs is experiencing robust growth, fueled by increasing demand for food security, ornamental plants, and specialized agricultural products. This trend underscores the importance of reliable suppliers for indole-3-butyric acid for sale and the innovative applications of naphthalene acetic acid uses in plants across diverse climatic zones and cultivation systems. Industry stakeholders are increasingly seeking products that offer high efficacy, environmental compatibility, and consistent performance, reflecting a shift towards more precise and sustainable agricultural inputs.

Technical Deep Dive: Key Parameters & Specifications of IBA and NAA

The effectiveness of plant growth regulators hinges significantly on their chemical purity, formulation, and precise technical parameters. Both Indole-3-Butyric Acid and Naphthalene Acetic Acid possess distinct chemical properties that dictate their application and efficacy. IBA, with its chemical formula C12H13NO2, is celebrated for its exceptional rooting capabilities, making it a cornerstone for vegetative propagation. Conversely, NAA, characterized by C12H10O2, exhibits broader applications, including fruit thinning, preventing premature fruit drop, and promoting flowering.

When sourcing indole-3-butyric acid for sale or evaluating suppliers for 1 naphthaleneacetic acid, critical parameters such as purity (typically >98% for technical grade), solubility, melting point, and stability under various environmental conditions must be rigorously assessed. These specifications directly impact the product's shelf life, ease of formulation, and, most importantly, its biological activity in plants. High-grade products ensure minimal impurities, which could otherwise lead to phytotoxicity or reduced effectiveness. Below is a comparative table detailing key technical parameters for these essential PGRs.

Parameter | Indole-3-Butyric Acid (IBA) | Naphthalene Acetic Acid (NAA) |

Chemical Formula | C12H13NO2 | C12H10O2 |

Molecular Weight | 203.24 g/mol | 186.21 g/mol |

Purity (Min.) | 98% (Technical Grade) | 98% (Technical Grade) |

Melting Point | 123-125 °C | 132-135 °C |

Solubility in Water | Slightly Soluble (40-50 mg/L) | Slightly Soluble (420 mg/L) |

Appearance | White to off-white crystalline powder | White crystalline powder |

These parameters are foundational for formulating effective plant growth solutions. Manufacturers dedicated to providing top-tier indole-3-butyric acid for sale and refined 1 naphthaleneacetic acid ensure their products meet or exceed these specifications, guaranteeing consistency and reliability for agricultural applications globally.

Manufacturing Process & Quality Assurance for Superior PGRs

The production of high-grade Indole-3-Butyric Acid and Naphthalene Acetic Acid involves sophisticated chemical synthesis and rigorous purification protocols to ensure maximum efficacy and safety. The manufacturing process typically begins with precursor chemicals that undergo a multi-step reaction, often involving esterification, hydrolysis, and crystallization. For example, the synthesis of IBA usually involves the reaction of indole with butyrolactone derivatives, followed by subsequent transformations to yield the desired indole-3-butyric acid. Similarly, 1 naphthaleneacetic acid is synthesized from naphthalene, often through oxidation and subsequent carboxylation steps.

Critical to the quality of indole-3-butyric acid for sale and naphthalene acetic acid uses in plants is the downstream purification process. This involves techniques such as recrystallization, activated carbon treatment, and chromatographic separation to remove impurities and unwanted by-products, ensuring the final product meets stringent purity standards. Advanced manufacturing facilities adhere to international quality management systems like ISO 9001 and Good Manufacturing Practices (GMP) to guarantee traceability, consistency, and compliance. Rigorous detection standards, including High-Performance Liquid Chromatography (HPLC) for purity analysis and Mass Spectrometry (MS) for structural confirmation, are employed at every stage.

The lifespan and effectiveness of these PGRs are directly linked to their manufacturing quality. Products manufactured with precision and subject to stringent quality control offer superior stability, leading to predictable and consistent plant responses. These high standards are crucial for applications across various industries, including large-scale agriculture, ornamental plant nurseries, and scientific research. By focusing on advanced manufacturing processes and meticulous quality checks, leading suppliers ensure that their indole-3-butyric acid for sale and 1 naphthaleneacetic acid products deliver exceptional performance and reliability in all demanding scenarios.

Application Scenarios & Technical Advantages of IBA and NAA

The distinct biological activities of Indole-3-Butyric Acid and Naphthalene Acetic Acid lead to specialized applications across diverse horticultural and agricultural practices. IBA is primarily celebrated for its efficacy in promoting root formation, making it indispensable for vegetative propagation via cuttings. Its ability to stimulate adventitious root development significantly increases the success rate of propagation for a wide range of plants, from ornamentals to fruit trees. This rooting hormone minimizes transplant shock and accelerates the establishment of young plants, leading to healthier, more robust growth.

On the other hand, naphthalene acetic acid uses in plants are broader and encompass several critical growth management tasks. NAA is effectively employed for fruit thinning in orchards (e.g., apples, pears) to improve fruit size and quality by reducing competition among developing fruits. It also plays a vital role in preventing premature fruit drop, ensuring a higher yield at harvest. Furthermore, NAA can be used to induce flowering in certain crops and to control sprout growth in stored potatoes and onions. The precise application rates and timing for both IBA and NAA are crucial for achieving desired results without causing phytotoxic effects, underscoring the importance of expert guidance and high-purity products.

Advantage Category | Indole-3-Butyric Acid (IBA) | Naphthalene Acetic Acid (NAA) |

Primary Use | Rooting hormone for cuttings, transplant shock reduction. | Fruit thinning, preventing fruit drop, flowering induction, sprout inhibition. |

Rooting Efficacy | Superior and broad-spectrum rooting activity across plant species. | Less pronounced rooting effect compared to IBA, but still effective in some cases. |

Stability | Generally stable in formulations, good shelf life for indole-3-butyric acid for sale. | Stable under proper storage, critical for fruit management. |

Versatility | Key for nurseries, tissue culture, and home gardening. | Essential for commercial orchards, vegetable growers, and storage facilities. |

Compatibility | Often blended with fungicides or other PGRs for comprehensive propagation solutions. | Can be tank-mixed with other agrochemicals, with careful consideration. |

The strategic choice between, or combination of, these PGRs allows for tailored plant management solutions. Suppliers of indole-3-butyric acid for sale and 1 naphthaleneacetic acid who also offer technical support can guide growers in optimizing their application protocols for specific crop types and desired outcomes, maximizing the return on investment for these valuable agricultural inputs.

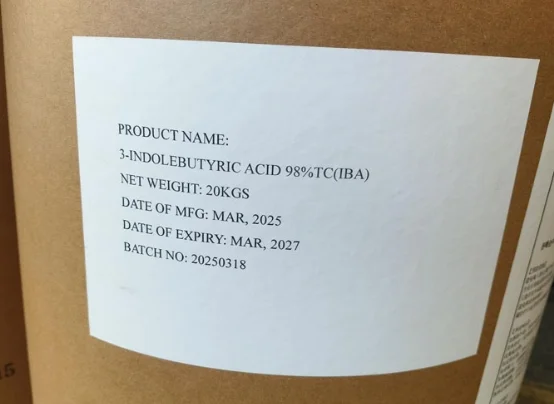

Product Spotlight: High-Purity 3-INDOLEBUTYRIC ACID

Our flagship product, high-purity 3-INDOLEBUTYRIC ACID, stands as a testament to advanced chemical synthesis and stringent quality control, providing superior performance for a multitude of plant propagation applications. This premium-grade indole-3-butyric acid for sale is meticulously manufactured to achieve a minimum purity of 98%, ensuring consistent and reliable results. Its excellent solubility in organic solvents and moderate water solubility facilitate easy formulation into various application forms, including powders, gels, and liquid solutions, catering to diverse operational needs in nurseries, greenhouses, and large-scale agricultural settings.

The unparalleled effectiveness of 3-INDOLEBUTYRIC ACID lies in its ability to stimulate robust and uniform root development in plant cuttings, significantly reducing rooting time and increasing the overall success rate of propagation. Its application supports the rapid establishment of young plants, leading to stronger root systems that are more resilient to environmental stresses and transplant shock. This product is indispensable for propagating economically important crops, rare species, and ornamental plants, offering a competitive edge to professional growers. Below are the key technical specifications for our 3-INDOLEBUTYRIC ACID.

Technical Parameter | Specification for 3-INDOLEBUTYRIC ACID |

Assay (Purity) | ≥ 98.0% |

Loss on Drying | ≤ 0.5% |

Residue on Ignition | ≤ 0.1% |

Heavy Metals (as Pb) | ≤ 10 ppm |

pH (1% solution) | 3.5 – 4.5 |

Storage Stability | Stable for 2 years under cool, dry conditions. |

Visualizing the quality and performance metrics helps underscore the product's reliability. A typical Pie Chart illustrating the Purity Distribution of 3-INDOLEBUTYRIC ACID would show over 98% as the active ingredient, with minimal percentages for moisture, ash, and trace impurities, affirming its high-grade nature. Furthermore, a Line Chart comparing the Rooting Efficacy of 3-INDOLEBUTYRIC ACID Formulations against lower-grade alternatives would consistently demonstrate superior root mass, root length, and faster rooting initiation with our premium product, providing clear data on its enhanced performance for commercial applications where efficient rooting is critical for business success.

Choosing Your Partner: Manufacturer Comparison & Custom Solutions

Selecting the right supplier for plant growth regulators like indole-3-butyric acid for sale and 1 naphthaleneacetic acid is a strategic decision that can significantly impact agricultural productivity and profitability. A reputable manufacturer differentiates itself through consistent product quality, robust R&D capabilities, comprehensive technical support, and adherence to international regulatory standards. Key evaluation criteria for potential partners include their manufacturing certifications (e.g., ISO 9001, REACH compliance), their track record of quality assurance, and their ability to provide certified Certificates of Analysis (CoA) for every batch.

Beyond standard product offerings, the capacity for customized solutions is a hallmark of a premier partner. Many B2B clients require specific formulations, concentrations, or blended PGR products to suit unique crop requirements or application methods. A manufacturer capable of offering tailored solutions, whether it's developing a specific granular formulation of indole-3-butyric acid for sale or a precise liquid concentrate of naphthalene acetic acid uses in plants, adds immense value. This collaborative approach ensures that the PGRs integrate seamlessly into existing agricultural protocols, optimizing performance and minimizing waste. Experienced manufacturers also provide expert guidance on application rates, safety protocols, and storage conditions, further enhancing customer success and trust.

Our commitment extends to fostering long-term partnerships through transparent communication, reliable supply chains, and continuous innovation. We understand that each client has distinct needs, and our team of chemists and agronomists is dedicated to developing bespoke solutions that drive agricultural excellence. Our service commitment, backed by years of industry experience, ensures clients receive not just products, but comprehensive solutions that contribute to their sustainable growth and market leadership in a competitive landscape.

Real-World Impact: Application Cases & Customer Success Stories

The tangible benefits of high-quality plant growth regulators are best illustrated through successful application cases. Consider a large-scale ornamental nursery specializing in difficult-to-root woody perennials. By adopting a specialized dipping solution containing our premium indole-3-butyric acid for sale, they observed a 25% increase in rooting success rates compared to their previous methods, alongside a 10-day reduction in the overall propagation cycle. This efficiency gain translated directly into increased plant output and higher revenue, solidifying IBA as an indispensable tool in their operations.

Another compelling example comes from a commercial apple orchard that faced challenges with inconsistent fruit size and premature fruit drop. Implementing a precise spraying regime of naphthalene acetic acid uses in plants during critical developmental stages allowed them to effectively thin overly dense fruit sets and prevent significant pre-harvest drop. Post-harvest analysis revealed a 15% improvement in marketable fruit size and a 5% reduction in harvest losses due to premature drop, leading to a substantial enhancement in yield quality and profitability. These cases underscore the practical, economic advantages derived from utilizing scientifically-backed and rigorously tested PGRs.

Our long-standing partnerships with leading agricultural enterprises and research institutions globally bear testament to the consistent performance and reliability of our products. Feedback from our clients consistently highlights the purity, efficacy, and superior support they receive, enabling them to achieve their cultivation goals with greater confidence and efficiency. These success stories are a cornerstone of our commitment to excellence, reflecting our deep experience in delivering impactful solutions to the B2B sector, reinforcing why our 1 naphthaleneacetic acid and IBA products are trusted globally.

Ensuring Trust & Reliability: Guarantees & Support

Trust is the bedrock of any successful B2B relationship, especially when dealing with critical agricultural inputs like plant growth regulators. We back our commitment to quality with comprehensive certifications and unwavering customer support. Our manufacturing processes are compliant with international standards, including ISO 9001 for quality management systems, ensuring every batch of indole-3-butyric acid for sale and 1 naphthaleneacetic acid meets the highest purity and performance benchmarks. Furthermore, our products adhere to relevant regulatory frameworks like REACH, demonstrating our responsibility towards environmental safety and human health.

We offer detailed Certificates of Analysis (CoA) with every order, providing complete transparency regarding product specifications, purity levels, and test results. Our stringent internal quality control protocols complement third-party verification, reinforcing the reliability of our PGRs. In terms of logistics, we understand the importance of timely delivery; our robust supply chain management ensures efficient processing and dispatch, with clear communication on estimated delivery cycles. A comprehensive quality warranty accompanies all our products, providing peace of mind and demonstrating our confidence in their efficacy and stability. Should any technical queries arise concerning naphthalene acetic acid uses in plants or IBA applications, our dedicated technical support team is readily available to provide expert guidance and troubleshooting.

Our service history spans over two decades, during which we have cultivated a reputation for integrity and excellence. This extensive experience, combined with a strong network of satisfied clients across diverse agricultural sectors, underpins our authoritativeness in the PGR market. We believe in building enduring partnerships, providing not just products, but a complete ecosystem of support designed to foster growth and success for our clients globally, reinforcing the trustworthiness of our brand and products.

Frequently Asked Questions (FAQ) about PGRs

Q1: What purity level should I look for when purchasing indole-3-butyric acid for sale?

A1: For professional and commercial applications, a minimum purity of 98% (technical grade) is highly recommended. This ensures optimal biological activity and minimizes the risk of introducing impurities that could negatively impact plant health or product efficacy.

Q2: How do naphthalene acetic acid uses in plants differ from IBA applications?

A2: IBA is predominantly used for promoting root development in cuttings, enhancing vegetative propagation. NAA, while also having some rooting capabilities, is more widely applied for fruit thinning, preventing premature fruit drop, and inducing flowering in various crops.

Q3: What are the recommended storage conditions for 1 naphthaleneacetic acid?

A3: NAA should be stored in a cool, dry, well-ventilated area, away from direct sunlight and moisture. The original sealed container is ideal, typically maintaining stability for up to two years when stored properly.

Q4: Can these PGRs be custom blended for specific agricultural needs?

A4: Yes, leading manufacturers offer custom blending services to create formulations with specific concentrations or combinations of PGRs, tailored to individual crop types, environmental conditions, or application methods. This allows for optimized performance and efficiency.

Q5: What certifications should a reliable supplier of indole-3-butyric acid for sale possess?

A5: Look for suppliers with ISO 9001 certification for quality management, and adherence to relevant chemical regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) if operating in European markets. Third-party testing and Certificates of Analysis are also crucial.

Q6: Are there any environmental considerations when using PGRs?

A6: Yes, responsible use is critical. Always follow label instructions for application rates and safety precautions. Proper disposal of excess product and rinse water is essential to minimize environmental impact. High-purity products reduce the introduction of unwanted chemicals into the environment.

Q7: What is the typical delivery timeframe for bulk orders of PGRs?

A7: Delivery times can vary based on quantity, destination, and current stock. However, a reliable supplier typically provides clear lead times, often ranging from 7-14 business days for standard orders, with expedited options potentially available for urgent requirements. Custom orders may require longer production schedules.

Conclusion & Future Outlook

The strategic application of high-quality plant growth regulators, particularly Indole-3-Butyric Acid and Naphthalene Acetic Acid, remains a cornerstone of efficient and productive agriculture and horticulture. From enhancing propagation success with indole-3-butyric acid for sale to optimizing fruit yield with naphthalene acetic acid uses in plants, these powerful compounds are essential tools for modern growers. As the agricultural industry continues to face challenges such as climate change and increasing global food demand, the role of precise, scientifically-backed inputs like PGRs will only grow in importance.

Looking forward, innovation in PGR synthesis, formulation, and application technology will be key. Manufacturers committed to rigorous quality control, sustainable practices, and tailored customer solutions will lead the way, providing the advanced 1 naphthaleneacetic acid and IBA products necessary for a resilient and thriving agricultural future. Partnering with a trusted expert ensures access to not only superior products but also the knowledge and support required to navigate the complexities of plant science and achieve unparalleled success.

References

1. Davies, P. J. (2004). Plant Hormones: Physiology, Biochemistry and Molecular Biology. Kluwer Academic Publishers.

2. Taiz, L., Zeiger, E., Møller, I. M., & Murphy, A. (2015). Plant Physiology and Development. Sinauer Associates.

3. PGRSA. (n.d.). Plant Growth Regulation Society of America. (Authoritative industry body for plant growth regulators)

4. Hartmann, H. T., Kester, D. E., Davies, F. T., & Geneve, R. L. (2011). Hartmann & Kester's Plant Propagation: Principles and Practices. Prentice Hall.

5. Rademacher, W. (2015). Plant Growth Regulators: Their Role in Horticulture and Agriculture. Journal of Plant Growth Regulation, 34(4), 811-821.