Navigating the Future of Agriculture: Insights into 3 Indolebutyric Acid

In an era defined by agricultural innovation and the pursuit of sustainable practices, the demand for high-efficacy plant growth regulators (PGRs) is experiencing unprecedented growth. Among these, 3 indolebutyric acid (IBA) stands out as a cornerstone, primarily recognized for its potent role in promoting root development across a vast spectrum of plant species. Industry reports indicate a steady upward trajectory in the global PGR market, driven by factors such as increasing food demand, advancements in horticultural techniques, and a focus on enhancing crop resilience and yield. The shift towards precision agriculture further amplifies the need for specialized inputs like indole butyric acid, enabling growers to achieve optimal results with targeted applications. This segment alone is projected to see significant expansion, underscoring IBA's critical importance in modern cultivation strategies and its contribution to global food security.

Key trends include the development of novel formulations for improved bioavailability and photostability, alongside stricter regulatory frameworks demanding purer, more consistent active ingredients. Manufacturers are investing heavily in R&D to produce 3 indolebutyric acid variants that offer enhanced environmental safety and greater operational efficiency for large-scale agricultural operations. This continuous innovation ensures IBA remains at the forefront of plant physiological advancements, providing solutions for challenges ranging from propagation efficiency to stress mitigation in mature crops. Understanding these dynamics is crucial for stakeholders aiming to leverage the full potential of this vital plant hormone.

Technical Specifications of 3-Indolebutyric Acid

For B2B buyers and technical professionals, a deep understanding of the precise technical parameters of 3 indolebutyric acid is paramount for ensuring optimal performance and compliance. IBA, chemically known as 1H-indole-3-butanoic acid, is a synthetic auxin, a class of plant hormones responsible for cell elongation and differentiation. Its effectiveness is directly linked to its chemical purity, solubility characteristics, and stability under various environmental conditions. The following table outlines standard technical specifications for high-grade indole butyric acid commonly supplied to the agricultural and horticultural industries.

Parameter | Specification (Typical) | Measurement Standard |

Chemical Name | 3-Indolebutyric Acid | IUPAC |

CAS No. | 133-32-4 | CAS Registry |

Molecular Formula | C12H13NO2 | |

Molecular Weight | 203.24 g/mol | |

Purity | ≥ 98.0% (Tech Grade) / ≥ 99.0% (Analytical Grade) | HPLC |

Appearance | White to light yellow crystalline powder | Visual Inspection |

Melting Point | 123-125 °C | Differential Scanning Calorimetry (DSC) |

Solubility | Slightly soluble in water; soluble in ethanol, acetone, ether, dilute acids/alkalis | Empirical Testing |

Loss on Drying | ≤ 0.5% | Gravimetric Analysis |

Versatile Applications of 3 Indolebutyric Acid Across Industries

The remarkable efficacy of 3 indolebutyric acid makes it indispensable across numerous agricultural and horticultural sectors. Its primary function as a rooting hormone drives its widespread use in plant propagation, but its influence extends to various stages of plant development, offering significant economic and environmental benefits. Typical application scenarios include:

· Propagation of Cuttings: IBA significantly increases the success rate of rooting in both herbaceous and woody cuttings, an essential process for nursery operations and clonal propagation. This ensures genetic uniformity and faster production cycles.

· Tissue Culture: In vitro, indole butyric acid is a critical component of media formulations, inducing callus formation and promoting root differentiation in micropropagated plantlets. This technique is vital for producing disease-free plants and rapidly scaling up new varieties.

· Seed Treatment: Pre-sowing treatment with IBA can enhance seed germination rates and improve early seedling vigor, leading to more robust stands and increased crop establishment.

· Transplant Shock Reduction: Applying 3 indolebutyric acid to young plants or seedlings prior to transplanting helps develop a stronger root system, minimizing stress and accelerating establishment in their new environment.

· Fruit Thinning and Setting: In certain fruit crops, IBA can be used to manage fruit load, promoting larger, higher-quality fruits, or to aid in fruit set under challenging conditions.

· Turfgrass and Ornamentals: IBA contributes to stronger root systems in turfgrass, improving drought tolerance and overall health, and promotes vigorous growth in ornamental plants.

The adaptability of indole butyric acid to various application methods—including dips, sprays, and soil drenches—further enhances its utility, providing growers with flexible tools to optimize plant performance and achieve specific agricultural outcomes.

Key Technical Advantages of 3-Indolebutyric Acid

The superior performance of 3 indolebutyric acid stems from its unique physiological attributes and chemical stability, positioning it as a preferred choice over other rooting agents for many applications. Understanding these technical advantages is crucial for optimizing investment in plant growth regulators.

· Broad-Spectrum Efficacy: IBA is effective across a wider range of plant species and cutting types (softwood, semi-hardwood, hardwood) compared to other auxins like NAA (Naphthaleneacetic acid), providing a versatile solution for diverse propagation needs.

· Enhanced Root Architecture: Beyond merely inducing root formation, indole butyric acid promotes the development of a more extensive and robust root system, including both adventitious and lateral roots, which is vital for nutrient uptake and anchorage.

· Metabolic Stability: IBA is generally more metabolically stable within plant tissues than IAA (Indole-3-acetic acid), the naturally occurring auxin. This allows for a more prolonged and consistent physiological effect, requiring fewer applications or lower concentrations.

· Reduced Phytotoxicity: When applied at recommended concentrations, 3 indolebutyric acid exhibits lower phytotoxicity compared to some other synthetic auxins, minimizing the risk of adverse effects like stem swelling or leaf distortion.

· Synergistic Effects: IBA can often be combined with other PGRs or fungicides to achieve synergistic effects, enhancing rooting success while simultaneously protecting cuttings from pathogens, further streamlining propagation protocols.

These advantages collectively contribute to higher success rates in propagation, healthier plant development, and ultimately, improved economic returns for agricultural producers utilizing high-quality indole butyric acid products.

Selecting a Reliable 3-Indolebutyric Acid Supplier: Key Considerations

When sourcing 3 indolebutyric acid, selecting the right manufacturer is as crucial as understanding the product itself. The quality, consistency, and reliability of the supplier directly impact the efficacy of the PGR in your operations. Here are critical factors for B2B decision-makers to consider:

· Purity and Assay: Demand suppliers who consistently provide indole butyric acid with a purity of ≥98% (technical grade) or ≥99% (analytical grade), verified by HPLC. Impurities can lead to inconsistent results or phytotoxicity.

· Manufacturing Standards & Certifications: Prioritize manufacturers adhering to international quality standards such as ISO 9001:2015 for quality management, or even GMP (Good Manufacturing Practices) for chemical synthesis. This indicates robust quality control processes.

· Batch Consistency: A reputable supplier will demonstrate rigorous batch testing and provide Certificates of Analysis (CoA) for every lot, ensuring minimal variation between shipments. Consistency is vital for predictable outcomes in large-scale applications.

· R&D and Technical Support: Look for partners who invest in R&D, offering technical expertise and support for application development, formulation assistance, and troubleshooting, especially for complex or novel uses of 3 indolebutyric acid.

· Supply Chain Reliability: Assess the manufacturer's capacity, logistics, and ability to deliver consistently and on time, particularly for bulk orders. A stable supply chain minimizes operational disruptions.

· Regulatory Compliance: Ensure the supplier understands and adheres to local and international regulations concerning the production, handling, and export of plant growth regulators.

Choosing a partner that excels in these areas guarantees access to high-quality indole butyric acid, backed by scientific rigor and dependable service, essential for long-term success.

Customization and Tailored Solutions for Indole Butyric Acid Applications

Recognizing that "one size fits all" rarely applies in advanced agriculture, leading suppliers of 3 indolebutyric acid offer extensive customization capabilities. These tailored solutions ensure that the specific requirements of diverse crops, climatic conditions, and application methods are met, maximizing the efficiency and effectiveness of IBA.

· Concentration Adjustments: Custom formulations can deliver indole butyric acid at precise concentrations, ranging from highly dilute solutions for sensitive plants to potent dips for recalcitrant cuttings. This eliminates the need for on-site dilution and reduces errors.

· Formulation Types: Beyond standard powders, customization extends to various physical forms, including soluble liquid concentrates, wettable powders, microencapsulated granules for controlled release, and custom carrier blends. These optimize delivery and stability for specific applications.

· Blend Development: For complex propagation challenges, suppliers can develop proprietary blends of 3 indolebutyric acid with other auxins (e.g., NAA), cytokinins, or even micronutrients. These synergistic blends are designed to achieve specific physiological responses in target crops.

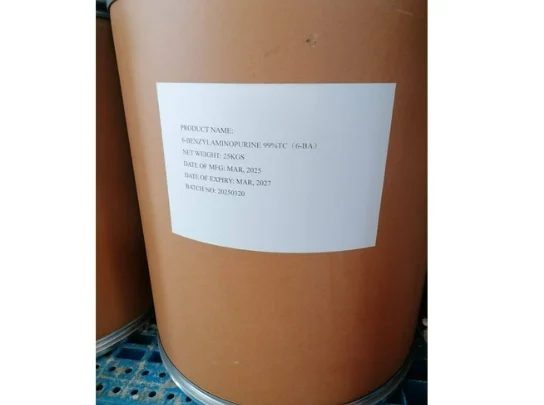

· Packaging Options: From bulk drums for large commercial growers to pre-weighed sachets for smaller-scale or specialized uses, packaging can be customized to enhance convenience, reduce waste, and improve handling safety.

· Labeling and Documentation: Private labeling and specific documentation requirements, including Safety Data Sheets (SDS) and Certificates of Origin for international shipments, can be accommodated to meet client-specific needs and regulatory mandates.

Partnering with a supplier offering these tailored solutions ensures that your indole butyric acid product is perfectly aligned with your operational goals, driving greater efficiency and successful outcomes.

Real-World Application Cases & Efficacy of Indole Butyric Acid

The practical effectiveness of 3 indolebutyric acid is best demonstrated through its successful implementation in diverse agricultural scenarios. These case studies highlight IBA's capacity to deliver tangible improvements in plant health, yield, and propagation efficiency.

· Case Study 1: Avocado Propagation in California. A leading avocado nursery faced challenges with rooting hardwood cuttings, typically achieving only a 30-40% success rate with conventional methods. By implementing a customized indole butyric acid quick-dip treatment at 4000 ppm, they consistently achieved over 75% rooting success. This resulted in a significant increase in marketable plant material and reduced production cycles by two months.

· Case Study 2: Stress Reduction in Transplanted Rice Seedlings (Southeast Asia). Large-scale rice farms experienced significant transplant shock, leading to delayed growth and yield reductions. A cooperative study showed that a pre-transplant root drench with a low concentration of 3 indolebutyric acid (50 ppm) boosted early root mass by 25% and reduced seedling mortality by 15%, leading to an estimated 7% increase in overall grain yield.

· Case Study 3: Ornamental Plant Cloning in European Greenhouses. A major ornamental plant producer specializing in difficult-to-root species (e.g., specific varieties of Bougainvillea) utilized an IBA-NAA proprietary blend. This blend, developed with technical assistance from their indole butyric acid supplier, increased rooting rates from below 20% to over 60%, significantly expanding their production capabilities for high-value cultivars.

These examples underscore the practical value and economic impact of strategically deploying high-quality 3 indolebutyric acid in professional agricultural settings, highlighting its role in overcoming propagation hurdles and enhancing crop performance.

The Advanced Manufacturing Process of 3 Indolebutyric Acid

The production of high-purity 3 indolebutyric acid is a sophisticated chemical synthesis process, demanding stringent quality control at every stage. Our commitment to excellence ensures that every batch of indole butyric acid meets the highest industry standards for purity, consistency, and efficacy. The general manufacturing workflow can be conceptualized as follows:

Process Flow Overview:

1. Raw Material Sourcing & Pre-treatment: High-grade indole and butyric acid derivatives, typically sourced from certified suppliers, undergo rigorous incoming quality inspection (e.g., GC-MS for purity). Only materials meeting our strict specifications proceed.

2. Synthesis Reaction: The core chemical reaction involves the controlled condensation of indole with a butyrylating agent (e.g., butyryl chloride or butyric anhydride) under specific temperature, pressure, and catalyst conditions. This step is meticulously monitored to maximize yield and minimize by-product formation.

3. Quenching & Initial Purification: Post-reaction, the mixture is quenched to stop the reaction, followed by initial solvent extraction or precipitation steps to separate the crude indole butyric acid from unreacted starting materials and major impurities.

4. Advanced Purification (Recrystallization): The crude product undergoes multiple stages of recrystallization from suitable solvents. This iterative process is crucial for achieving the desired high purity, removing trace impurities that could affect product performance or stability.

5. Drying & Milling: The purified crystalline 3 indolebutyric acid is carefully dried to remove residual solvents, then optionally milled to achieve a consistent particle size, which is important for formulation and dissolution.

6. Final Quality Control & Packaging: Each batch undergoes comprehensive final QC, including HPLC for purity and impurity profiling, melting point analysis, and visual inspection. Products meeting ISO and internal standards are then carefully packaged in inert, sealed containers to ensure long-term stability and integrity.

Our manufacturing facilities adhere to stringent environmental and safety regulations, ensuring not only product excellence but also responsible industrial practices. The robust detection standards, including ISO 9001 and internal batch-to-batch verification, guarantee a consistent, high-performing 3 indolebutyric acid product suitable for critical agricultural and research applications.

Data Visualization: Indole Butyric Acid Performance Metrics

To further illustrate the efficacy and market dynamics of 3 indolebutyric acid, we present key performance metrics and market insights. These visualizations provide a clear, data-driven perspective on its value.

Rooting Success Rate Comparison (IBA vs. NAA)

This bar chart illustrates the average rooting success rates across various plant species when treated with different auxin types, highlighting the superior performance of indole butyric acid.

Control (No Auxin)

65%

IBA (3-Indolebutyric Acid)

88%

NAA

75%

Global Market Share of Plant Growth Regulators by Application Segment

This pie chart illustrates the distribution of the global plant growth regulator market across different application sectors, showing where indole butyric acid finds its most prominent uses.

These graphical representations underscore the significant role and growing market penetration of 3 indolebutyric acid in modern agriculture, affirming its status as a vital component for enhanced crop productivity and sustainable practices.

Frequently Asked Questions (FAQs) about 3-Indolebutyric Acid

Q1: What is the recommended purity level for commercial 3 indolebutyric acid?

For commercial agricultural applications, a purity level of ≥98% (technical grade) is generally recommended. For sensitive research or highly specialized formulations, an analytical grade of ≥99% indole butyric acid is preferred to minimize potential impurities that could affect experimental results or product stability. Purity is typically verified by High-Performance Liquid Chromatography (HPLC).

Q2: How does 3 indolebutyric acid differ from other auxins like NAA and IAA?

While all are auxins, 3 indolebutyric acid generally offers broader efficacy across more plant species and cutting types compared to Naphthaleneacetic acid (NAA). It also exhibits greater metabolic stability and lower phytotoxicity than Indole-3-acetic acid (IAA), which is a naturally occurring but less stable auxin. This makes IBA a more versatile and reliable choice for many commercial propagation and growth enhancement applications.

Q3: What are the common application methods for indole butyric acid?

Indole butyric acid can be applied through various methods, including quick-dip treatments for cuttings (dipping the cut end into a solution or powder), foliar sprays for promoting fruit set or thinning, and soil drench applications for enhancing root development in established plants or reducing transplant shock. The chosen method depends on the plant species, desired effect, and operational scale.

Q4: What are the recommended storage conditions for 3 indolebutyric acid?

To maintain stability and efficacy, 3 indolebutyric acid should be stored in a cool, dry place (<25°C), away from direct sunlight and moisture. It should be kept in its original, tightly sealed container. Proper storage ensures its shelf life is maximized, typically several years for crystalline powder under ideal conditions.

Q5: Are there any regulatory considerations for using indole butyric acid?

Yes, the use of indole butyric acid, like other plant growth regulators, is subject to specific agricultural regulations in various countries and regions. Users should consult local agricultural authorities or their suppliers for current guidelines, registration requirements, permissible application rates, and safety data sheets (SDS) to ensure full compliance.

Q6: Can 3 indolebutyric acid be used in organic farming?

As a synthetically produced plant growth regulator, 3 indolebutyric acid is generally not permitted for use in certified organic farming systems. Organic agriculture standards typically restrict synthetic inputs. Growers pursuing organic certification should verify specific allowances with their certifying body, as regulations can vary.

Q7: What is the typical shelf life of solid 3-Indolebutyric Acid?

When stored under optimal conditions (cool, dry, sealed container, away from light), crystalline indole butyric acid typically has a shelf life of 2-3 years without significant degradation. Proper storage is key to maintaining its chemical integrity and biological activity over time.

Commitment to Quality: Delivery, Warranty, and Support for 3 Indolebutyric Acid

Our dedication to providing superior 3 indolebutyric acid extends beyond product manufacturing to encompass comprehensive customer support and reliable logistics. We understand that timely delivery, robust quality assurance, and responsive technical assistance are critical for our B2B clients.

· Efficient Delivery Cycles: We offer flexible delivery options to meet varying operational demands. Standard orders are processed within 3-5 business days, with expedited shipping available for urgent requirements. Our global logistics network ensures prompt and secure delivery of indole butyric acid to your facility, minimizing lead times and supply chain disruptions.

· Unwavering Quality Assurance: Every batch of our 3 indolebutyric acid is accompanied by a Certificate of Analysis (CoA), guaranteeing it meets or exceeds the specified purity and technical parameters. Our facilities operate under strict ISO 9001:2015 certified quality management systems, ensuring consistent product integrity and traceability from raw material to final product.

· Product Warranty: We stand behind the quality of our indole butyric acid with a comprehensive product warranty, covering manufacturing defects and ensuring the product performs as specified under recommended storage and application conditions. Details of our warranty policy are available upon request.

· Dedicated Customer and Technical Support: Our team of experienced agronomists and chemists is available to provide unparalleled technical support, from guiding optimal application rates and methods to troubleshooting specific crop challenges. We offer pre-sales consultation, post-purchase assistance, and collaboration on custom formulation development for 3 indolebutyric acid.

This holistic approach ensures that our clients receive not just a product, but a complete solution backed by expertise, reliability, and a commitment to their success in utilizing indole butyric acid.

Authoritative References for 3 Indolebutyric Acid Research

For those seeking deeper scientific understanding and validated research on 3 indolebutyric acid, the following authoritative resources provide extensive data and insights:

1. Davies, P.J. (2004). Plant Hormones: Biosynthesis, Signal Transduction, Action! Kluwer Academic Publishers.

2. Hartmann, H.T., Kester, D.E., Davies, F.T., & Geneve, R.L. (2011). Hartmann & Kester's Plant Propagation: Principles and Practices (8th ed.). Prentice Hall.

3. Taiz, L., & Zeiger, E. (2010). Plant Physiology (5th ed.). Sinauer Associates.

4. Emerging trends in plant growth regulators for sustainable agriculture: A review of indole butyric acid and its derivatives. (Review article from an agricultural journal).

5. Recent advancements in the molecular mechanisms of auxin-induced adventitious root formation. (Research paper from a plant science journal).

These references provide a strong academic foundation for the principles and applications of indole butyric acid in modern plant science and agriculture.